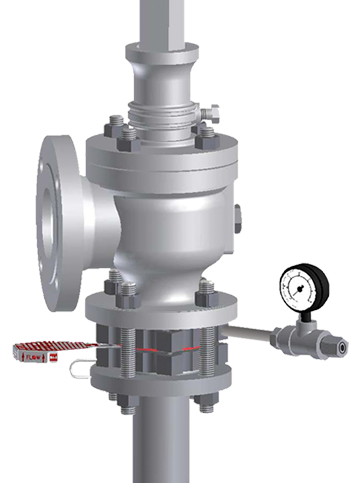

Relief Valve Isolated by a Rupture Disk

Advantages of Relief Valve Isolation with Rupture Disks

Codes & Standards permit the use of a rupture disk device at both a safety relief valve inlet

and outlet. The combination of rupture disk devices and safety relief valves continues to grow

driven by the user benefits of valve isolation including:

- Optimal leak tightness

- Increased operating pressure

- Extended valve life

- Reduced valve maintenance

- Improved corrosion resistance

- Viscous media compatibility

- Increased reliability

Optimal Leak Tightness

Isolating safety relief valves with rupture disk devices reduces the risk of fugitive emissions.

API Standard 526 defines that orifice F and smaller conventional safety relief valves shall have

a maximum allowable leakage rate of 40 bubbles per minute (approximately 6 cubic feet or 0.16

cubic meters per 24 hours). A solid metal rupture disk used at the inlet of the relief valve acts

as a barrier to this leakage.

Increased Operating Ratio

The most advanced reverse buckling disk technology permits operation to 95% of marked burst

pressure (100% of minimum burst pressure) isolating a safety relief valve from the most aggressive

pressure service conditions.

Extended Valve Life

The process barrier provided by the rupture disk device prevents product buildup from adhering to

mechanical components of the valve that otherwise could affect valve performance and safety of the

protected pressure system. The process media does not come in contact with internal surfaces and

parts of the valve, it will remain in new condition until called upon to relieve an overpressure event.

Reduced Valve Maintenance

With the valve internals not normally exposed to process contamination, they remain in ‘like new’

condition, allowing longer periods between major overhauls & less maintenance activity at each mandated cycle.

Improved Corrosion Resistance

The significant initial cost of a safety valve in exotic materials can be reduced by selecting less

costly material and isolating it with a rupture disk device. As an example, a Carbon Steel valve

with Hastelloy® trim might save 65% compared to the cost of a Hastelloy® valve. The savings will

fund the rupture disk device manufactured from Hastelloy® and reduce the need for frequent valve

service and associated costs.

Viscous Media Compatibility

Viscous fluids that might develop a blockage inside a valve mechanism due to leakage can be

isolated from the safety valve by a rupture disk device, increasing the integrity of the pressure

relief system. Rupture disks have typically a much lower thermal mass than a valve, protecting

the relief system from product solidification under normal service conditions.

Increased Reliability

The simplicity of rupture disk technology with no moving parts and no maintenance requirements adds

to the reliability of relief system design. The integrity of a safety relief valve that remains in

‘like new’ condition under normal process operating conditions maximizes the opportunity for valve

performance to meet the planned design safety requirements.